Capabilities

- Home

- Capabilities

An end-to-end service

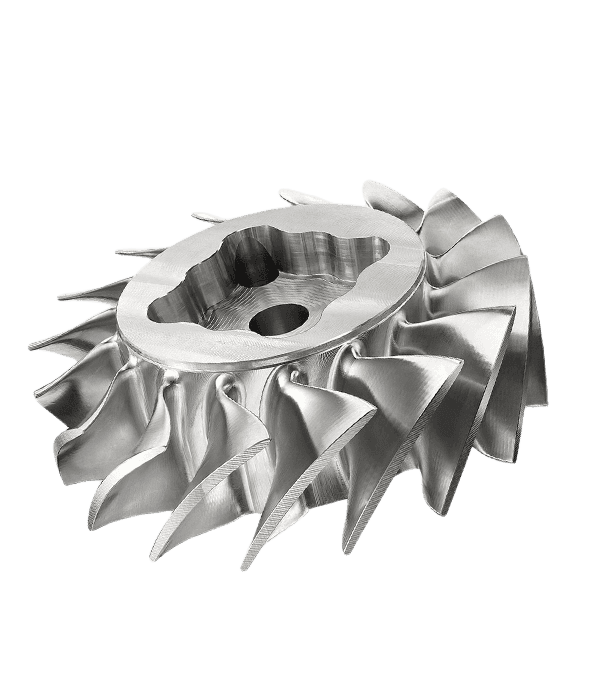

Advanced Precision Technologies capabilities are varied and flexible to customer requirements, ensuring we can provide engineering solutions to a wide range of industries and businesses.

From simple high volume turning and milling through to highly complex sliding head lathe work and low volume R and D, 5 axis milling programming, probing and machining we have the capabilities and experience to provide a cost effective, ‘right first time’ engineering solution within tight deadlines and extremely short lead times delivered on time.

Whether the customer requires a 3,4 or 5 axis part engineering / programming remotely or a full turnkey component manufacturing solution from quotation through to part inspection and delivery we can provide a cost effective, professional service from our site in Chatteris, Cambridgeshire, U.K.

Advanced Precision Technologies can also provide standalone 3,4 and 5 axis CNC programming utilizing Fusion360, FeatureCam and Openmind/Hypermill software packages.

How we work

- Analysis

- Design

- MANUFACTURE

Using our experience, we can analyse a component and optimize the design for manufacture together with a robust, streamlined engineering process to keep costs low and quality high taking into consideration the batch quantity, lifecycle of the component and the bespoke requirements of the customer.

D.F.M (design for manufacture) can create substantial savings and reduce cycle times significantly. At Advanced Precision Technologies we have gained the experience from 25 YEARS working in F1, Automotive and Medical R&D to reduce costs and cycle times significantly without compromising on quality.

We manufacture and design the fixtures and bespoke tooling to create robust processes for the parts our customers require on spec, on time.

We realise the importance of ‘right first-time components’ and will use our experience to choose the correct engineering process to ensure every part is within drawing spec whether it’s a 1 of or 10,000-part batch. In process part probing, predetermined C.L.R updates and thermal tracking are all utilized to ensure the components are always within specification.

GET IN TOUCH